Flexible shafts

Flexible shafts are the machine elements assigned to the transmission of motions between two axes which do not coincide or whose mutual position while working changes.

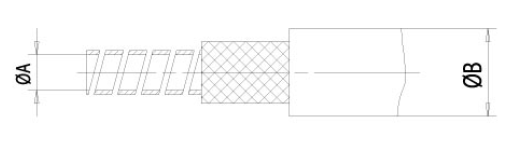

Flexible shafts are manufactured by winding up of quality steel wire in several layers.

Depending on application flexible shafts are divided as follows:

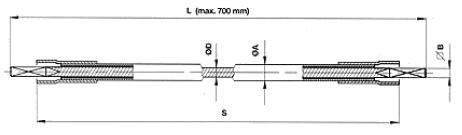

1. Flexible shafts for transmission of torque, in diameter up to Ø 6mm;

- Flexible shafts Ø 2,2 mm;

- Flexible shafts Ø 3,2 mm;

- Flexible shafts Ø 3,8 mm;

- Flexible shafts Ø 4,0 mm;

- Flexible shafts Ø 5,2 mm;

- Flexible shafts Ø 6,0 mm.

APPLICATION:

for control instruments and mostly for speed recording number of kilometers and operating time by the way of speed indicators, tachygraphs built into motorcycles, cars, trucks and tractors.

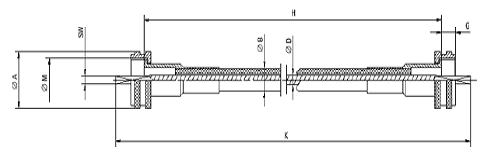

2. Flexible shafts prefer power transmission in diam. over Ø 6mm.

- Flexible shafts Ø 7,0 mm;

- Flexible shafts Ø 10,0 mm;

- Flexible shafts Ø 12,0 mm;

- Flexible shafts Ø 15,0 mm;

- Flexible shafts Ø 18,0 mm;

- Flexible shafts Ø 20,0 mm;

- Flexible shafts Ø 25,0 mm;

APPLICATION:

for transmission of energy from engine to tool-machines such as: pervibrators, movable drilling and grinding machines, tube cleaning devices, movable woodworking machines etc.

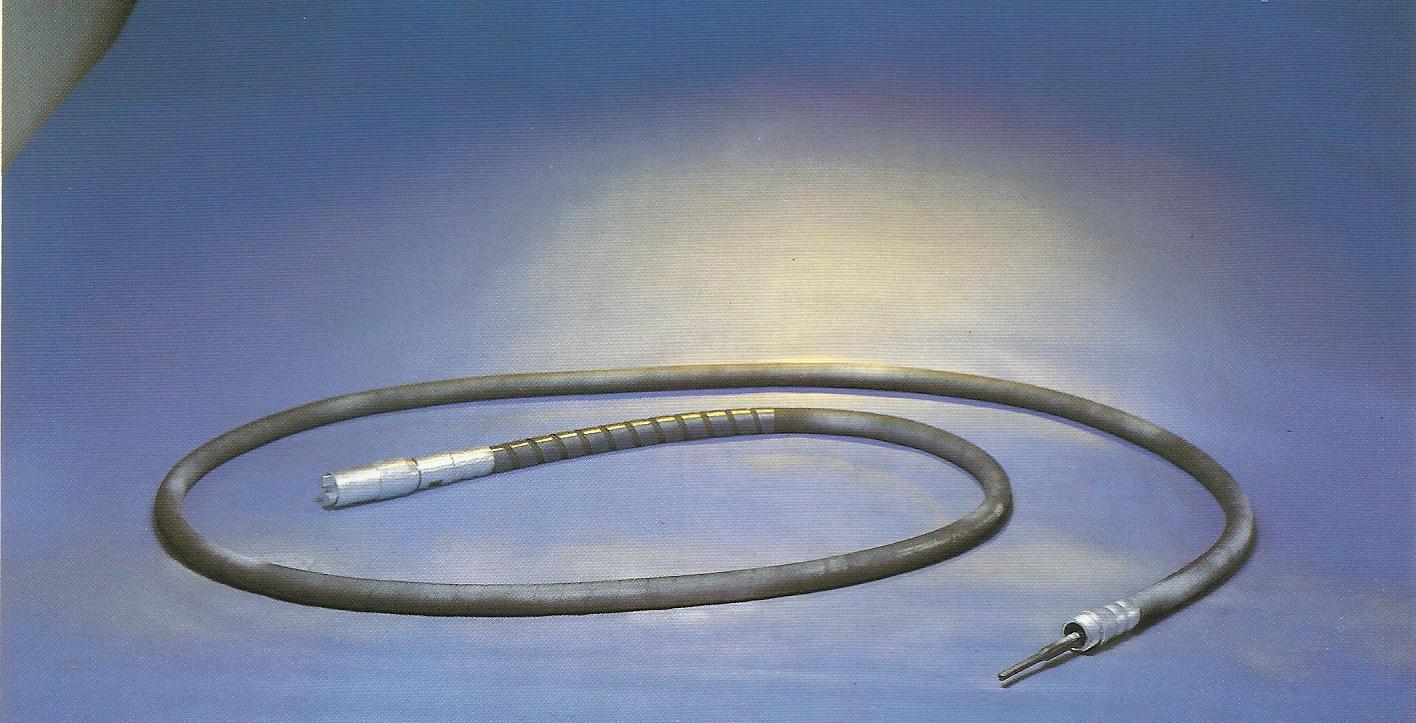

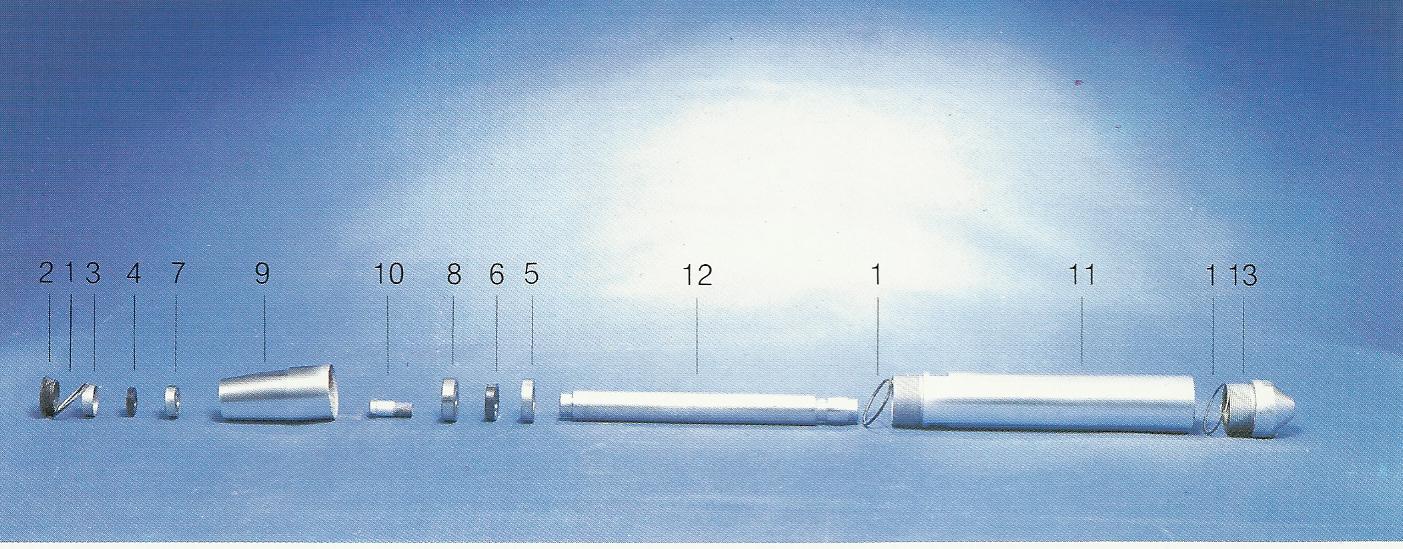

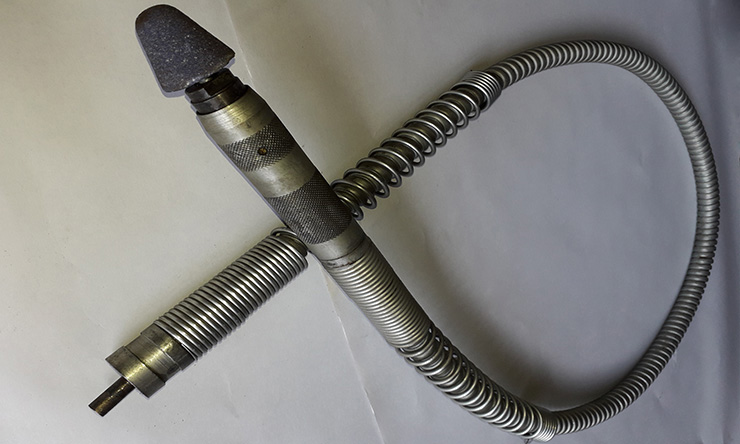

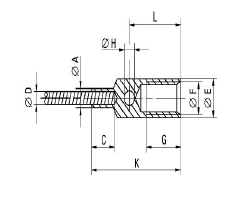

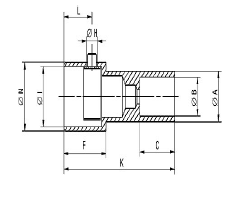

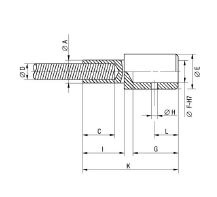

Flexible shafts, as a machine assembly, consists of metal protective covering coated with PVC lining, flexible shaft ( core) and two complete joints, one on drive side, another on instrument side.

The complete flexible shafts can be made with different joints on both sides and with different protective coverings.

In order to choose and to order the flexible shaft it is necessary to state the code of flexible shaft and number of pieces.

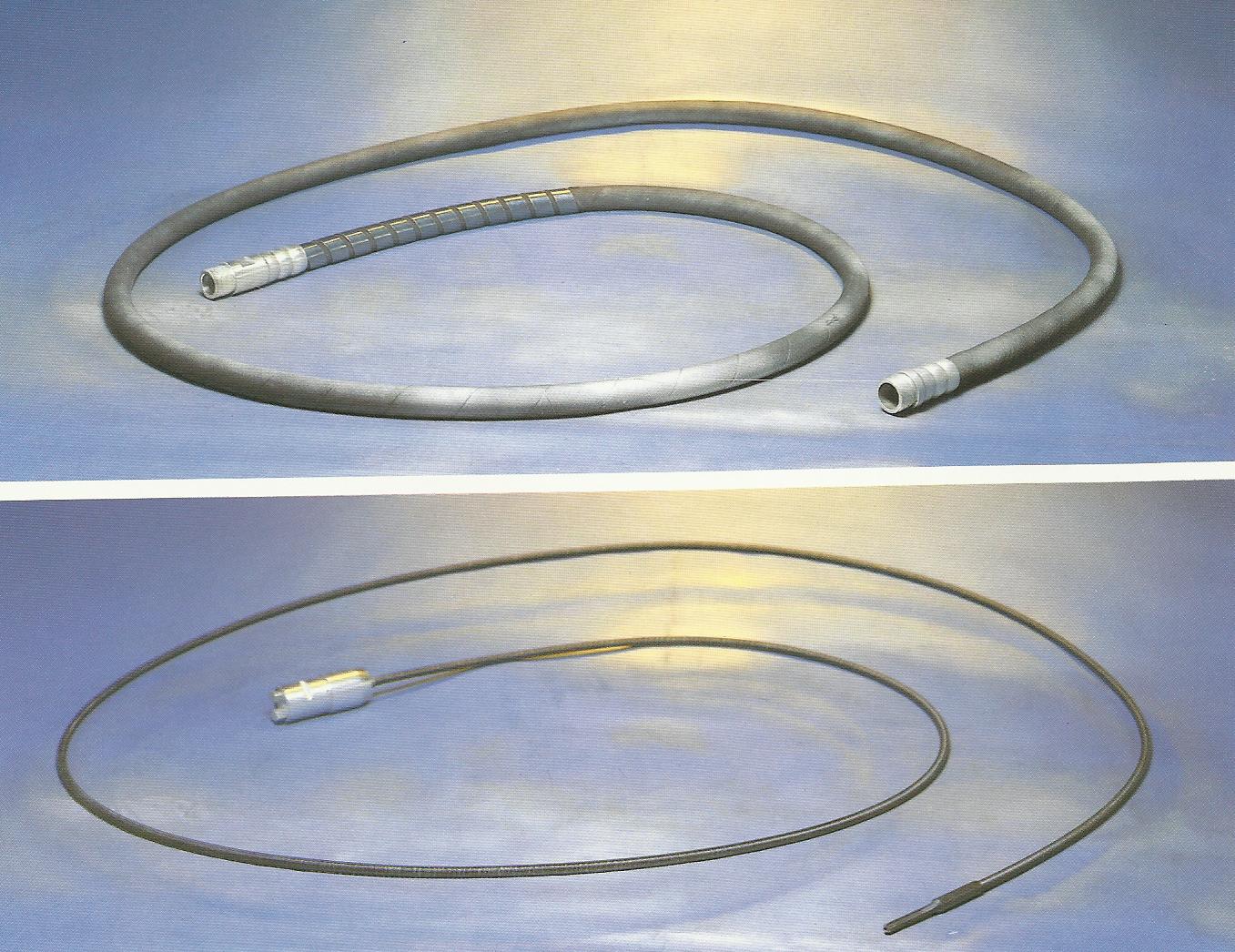

- up to Ø 12,0 mm have bin manufacturing bovden with PVC cover;

- and over Ø 12,0 mm it bovden is producing by metal flexible construction.

Except flexible shafts in our production program is enclosed products for transmission of the power and/or torque.

Assemblies ports are :

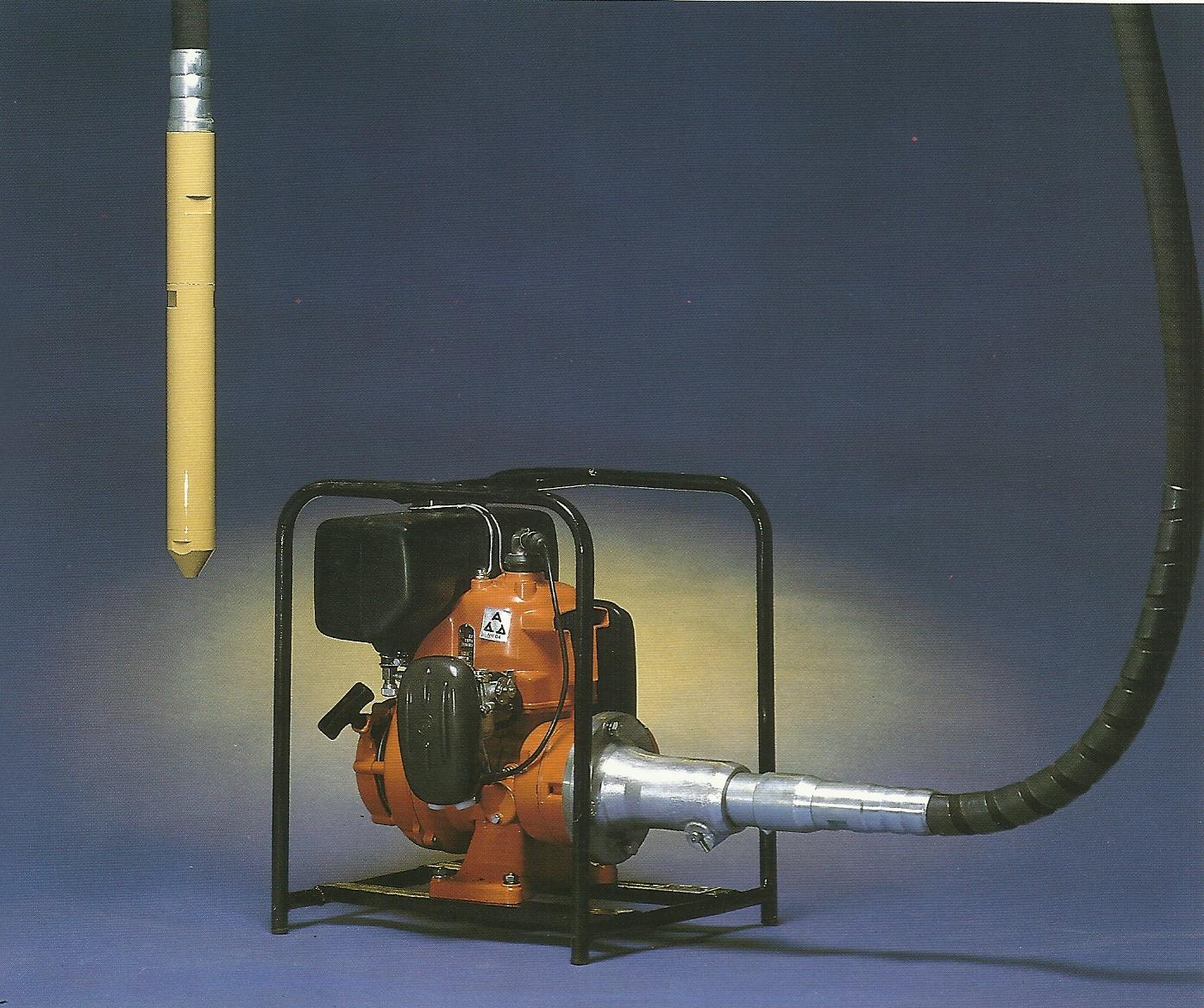

- two stork petrol engine - type UMO 06

- Flexible shafts - tip SV- 12M

- Vibro-head type VIG-M Ø 45

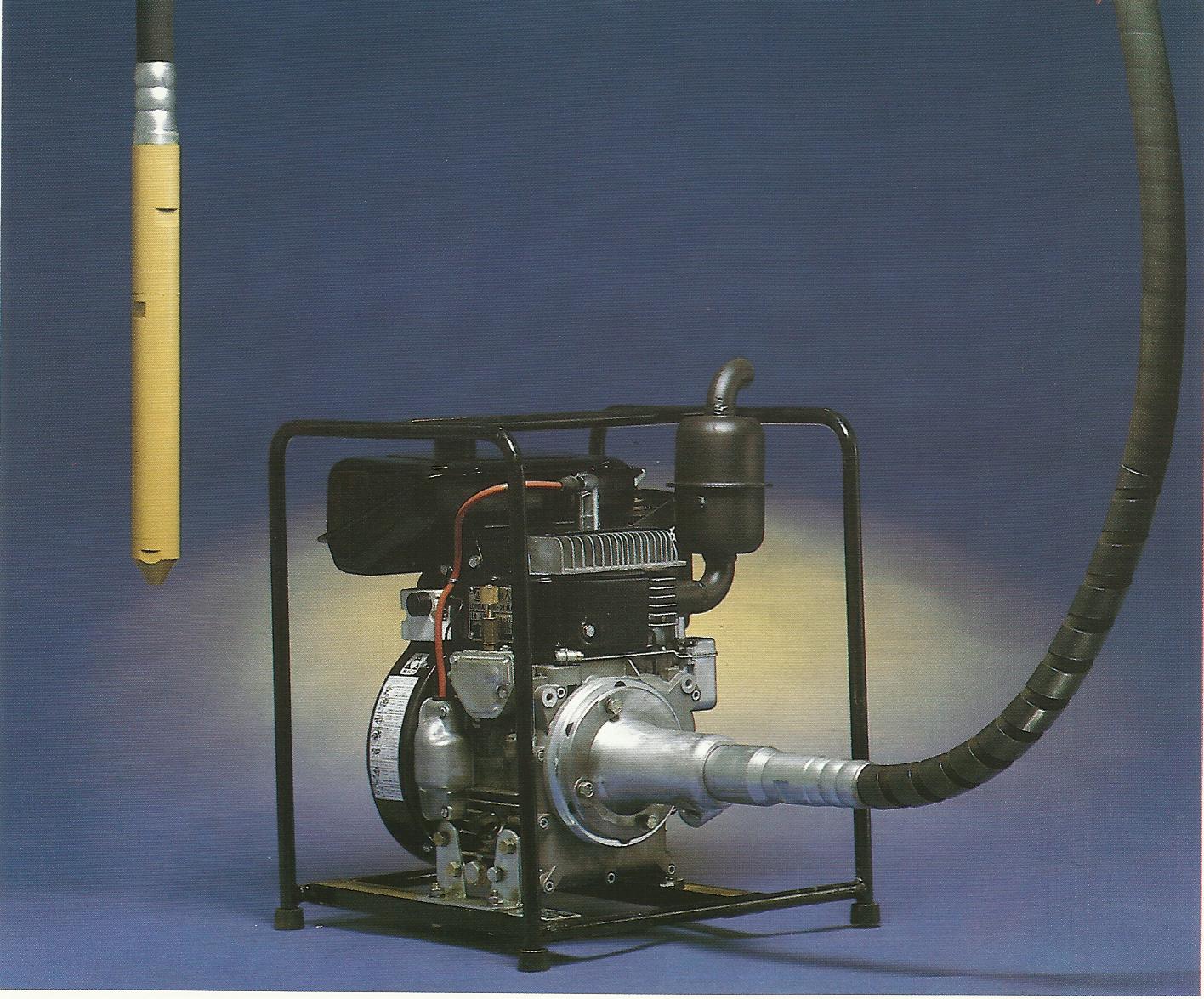

Assemblies ports are :

- four stork petrol engine - type LA 300

- Flexible shafts - tip SV- 12M

- Vibro-head type VIG-M Ø 60

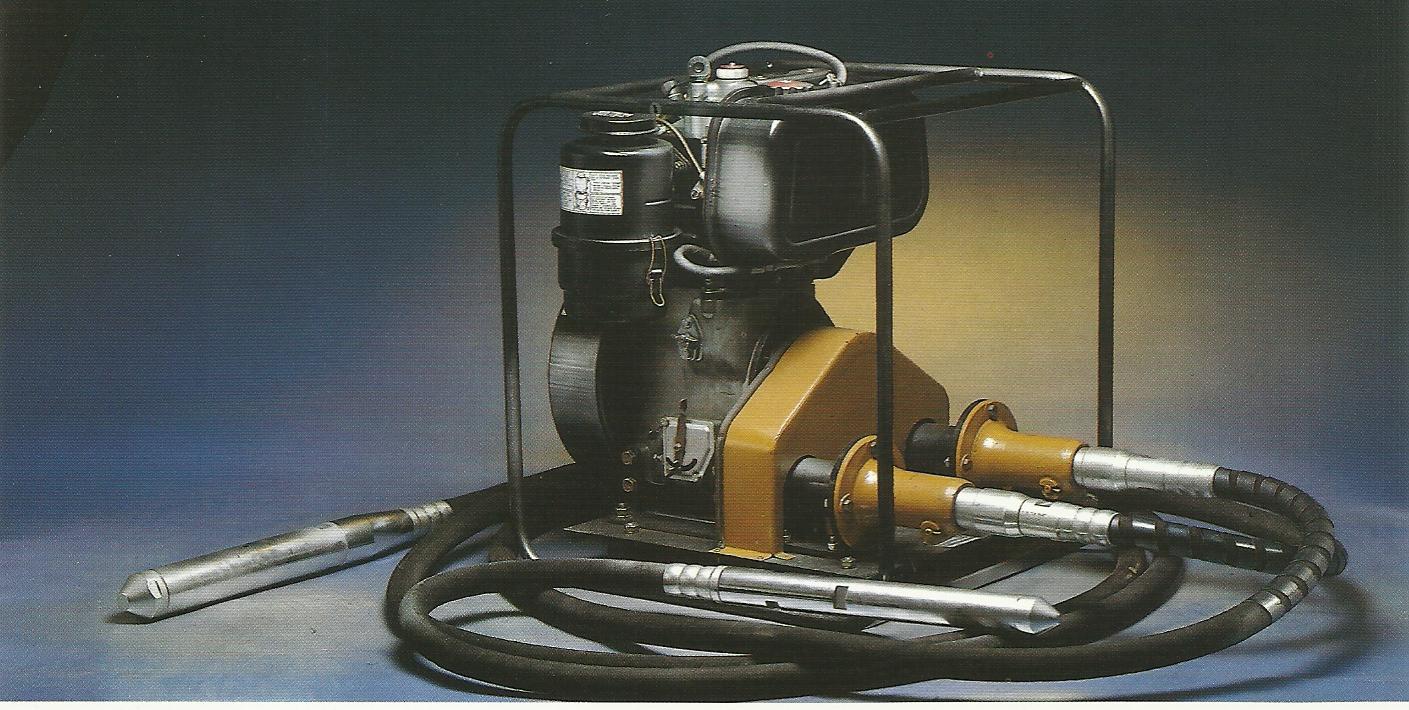

Assemblies ports are :

- four stork petrol engine - type LDA 450

- Flexible shafts - tip SV- 12M

- Vibro-head type VIG-M Ø 60

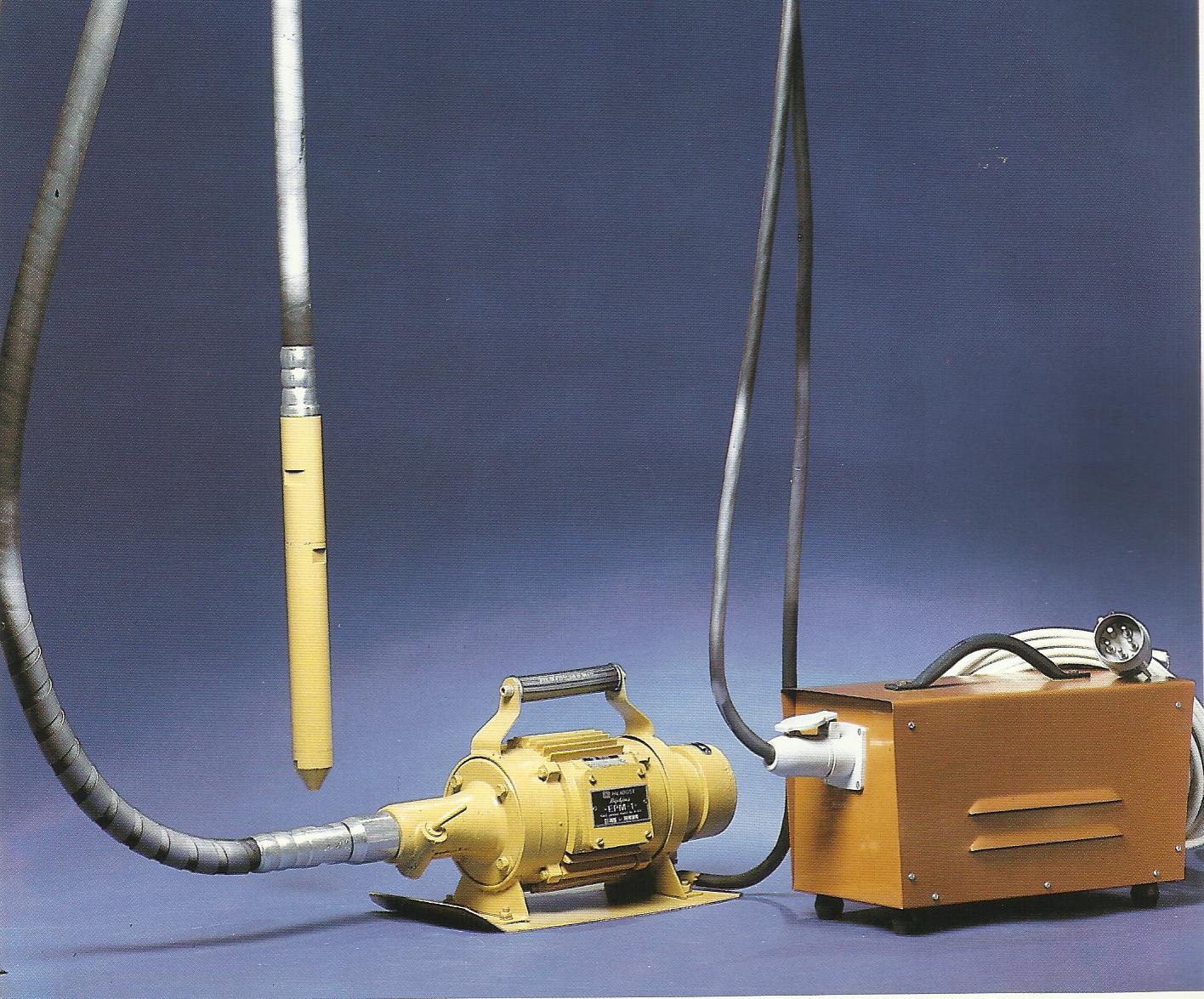

Assemblies ports are :

- Transformer with cable

- Electric motor

- Flexible shafts - tip SV- 12M

- Vibro-head type VIG-M Ø 45

- significantly higher quality of cleaning

- excluded the possibility of damage to pipes

- significantly shortening the time required for cleaning. Manual cleaning is performed by 5 workers for 15 hours while our device 2 workers performing the job for only 5 hours

- The savings in fuel consumption. Thanks to the quality of cleaning reduces the losses which can result in fuel savings that can be up to 10%

Devices can be used for cleaning all types of boiler tube of inner diameter DN 38 to DN 75 mm and lengths up to 13 m.

Operating principles:

The chuck positioned at the end of a flexible shaft which receives rotary motion from the electric motor is set brush or other cleaning tools. By insertion of a flexible shaft with chuck, and a brush for cleaning the tube and the rotation the brushes to remove plaque from the walls of the tube.

Thanks to the traits possessed by these devices are widely used in industrial process equipment, rubber, wood and glass industry, tool, pattern shop, foundry , hardware shops and other places for grinding and polishing tools, where the position is changed in all directions during the work and where other devices to access difficult or impossible.

Before starting work with the devices necessary do the following:

1. For three-phase drive motors to verify direction of rotation of the engine by comparing it with the arrow marks. In the case of the opposite direction of rotation of two phases to replace the plug. For single phase motor rotation direction is factory set.

2. Connect the flexible shaft to the drive motor and then connect the chuck with the proper tools.

3. After these actions the device is ready for work.

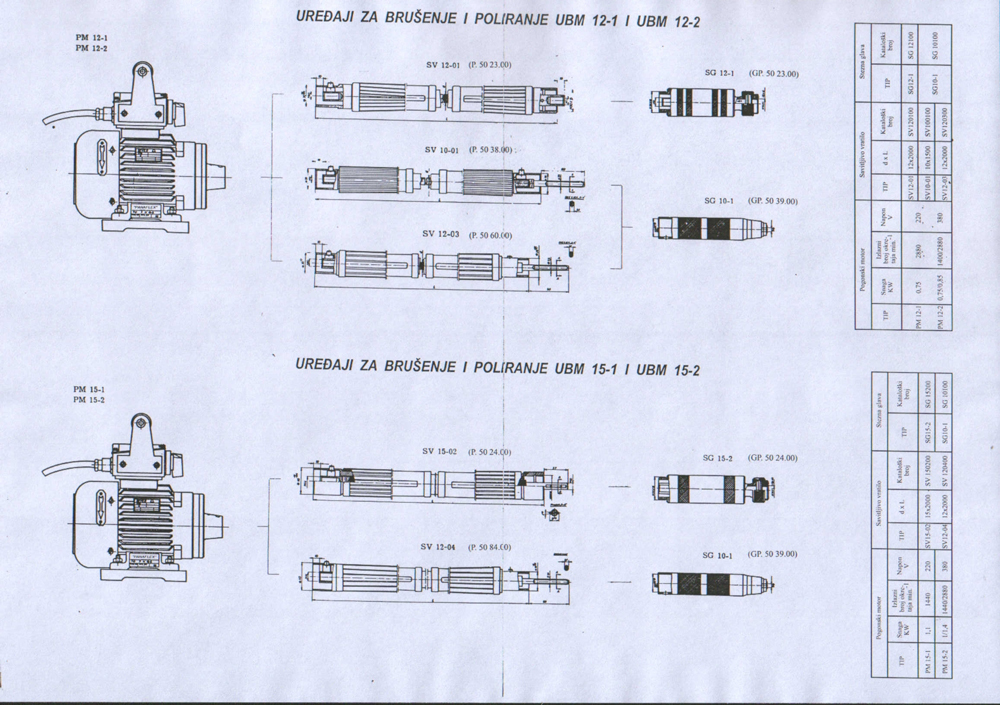

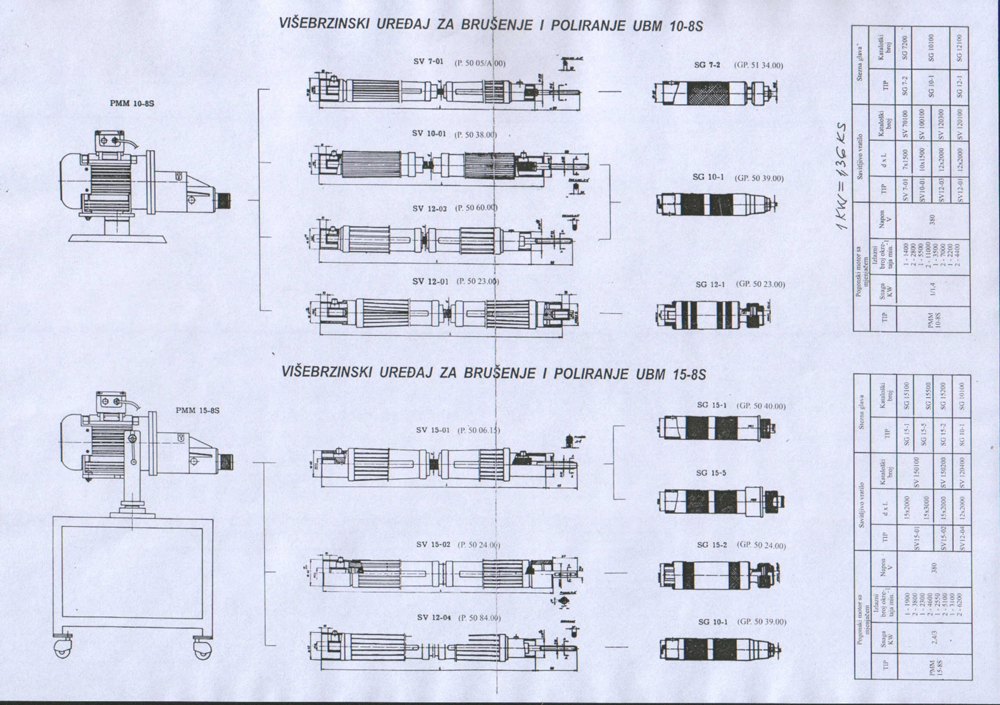

Apparatus for grinding and polishing UBM UBM 12-1 and 15-1 were mono phase with a single speed and UBM UBM 12-2 and 15-2 are phase two the number of revolutions and the UBM 15-2A, which is indirectly reduced. Change of speed is done by turning the switch in position 1 or 2with the proviso that it must ensure that during the transition from larger to smaller engine speed to a complete stop.

UBM devices and 10-8S 15-8S UBM are three phase. Change the number of turning them come in the following way: pick up the fuse lever, turn a bit eccentric until the required speed appears on the housing slot and then turn the cam to the right until it snaps in the fuse groove. With regard to the two eccentric read speed, the upper smaller number is obtained when the switch drive motor is in position 1 and the lower higher speed when the switch is in second position Change the number of revolutions made only when the engine is idle.

Application:

is for the most part activate of working devices removed from commanded point. in the use for railroad vehicles, industry of agricultural machines, shipbuilding and machinery one.

Technical data:

- Working scope: 150mm,70mm

- max. lenght: 5000mm

- Max. allowed load on elangation 10 KN

- Max. allowed load on pressure 2,5 KN

- Useful work 97 %

- min. bend radius 200 mm

- elastic deformat for load of 100 N 0,05 mm/m

| 1.700 mm | 1.877 mm | 2.100 mm | 2.300 mm | 2.400 mm | 2.830 mm | 3.100 mm |

3.300 mm | 3.700 mm | 4.000 mm | 4.450 mm | 5.200 mm | 5.700 mm |

|---|

or according customer's request.