APA and GUPA

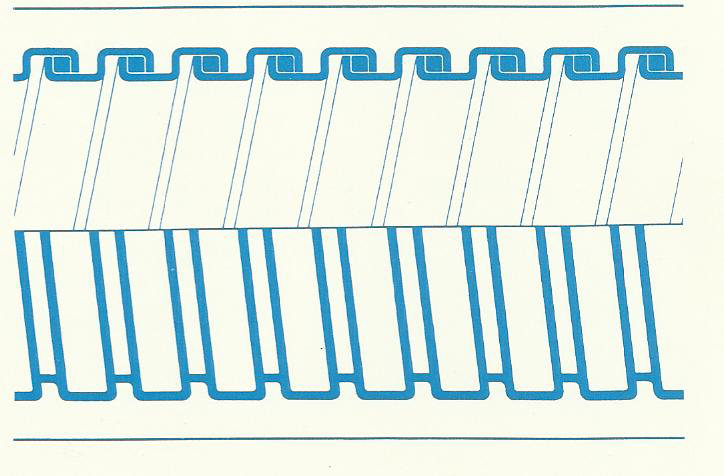

Flexible metallic strip wound tubes are manufactured from a helically wound pre-formed strip, generally with right-hand lead where the turns, with or without packing, are connected together by single or double overlapping. The flexibility is obtained by sliding adjacent turns on each other.

There are three types of strip wound tubes distinguished by their principle of manufacture and sealing characteristic:- leak proof tubes: suitable in applications for pressure (pressure tubes),

- tubes with limited leak profess: suitable in applications with low pressures and permissible leakage loss of fluid (extraction and exhaust tubes),

- non-leak proof tubes: suitable in applications without pressure (protective tubes).

MATERIAL

Flexible metallic tubes usually in heavy-duty conditions. In comparison with rigid tubes, they have less thickness of wall and therefore shall have superior anti-corrosive. The ideal materials to be used in the manufacture of flexible metallic tubes must meet the following requirements:

- working ability by plastic deformation,

- good strength properties,

- optimum thermal stability,

- anti-corrosive properties,

- reliability in operation.

- stainless steel AISI 304 W.Nr. 1.4301,

- galvanized steel

APA and GUPA

(polygonal and round cross section)

DESCRIPTION:

Tubes with limited leakprofness of polygonal or round cross section made by single overlapping.

Types: APA and GUPA are distinguished only by sealing thread type.

- APA: glass fiber.

- GUPA: rubber.

MATERIAL:

Galvanized steel and stainless steel

DIAMETERS:

DN 20 to DN 400.CONNECTING ELEMENTS:

Flanges, sleeves.

TEMPERATURES:

GUPA: from - 20 to + 60 º C

APPLICATION:

APA: Conveying of hot air, exhausting gases of engines, gases at welding etc.

GUPA: Conveying of air, saw dust in woodworking industry etc.

Technical characteristics "APA"

| A P A | ||||

|---|---|---|---|---|

| diameter ( mm) | minimal bending radius +10% | mass tol. ± 10% | ||

| nominal inside | outside | tolerance | ||

| DN=d (mm) | D (mm) | ± mm | Rmin(mm) | kg/m |

| 6 | 8,5 | 0,2 | 38 | 0,084 |

| 8 | 10,5 | 0,3 | 45 | 0,137 |

| 10 | 12,5 | 0,3 | 55 | 0,168 |

| 12 | 14,7 | 0,3 | 60 | 0,197 |

| 15 | 17,7 | 0,3 | 70 | 0,241 |

| 20 | 22,7 | 0,3 | 88 | 0,314 |

| 25 | 28,5 | 0,5 | 108 | 0,475 |

| 32 | 35,5 | 0,5 | 135 | 0,599 |

| 40 | 44,6 | 0,5 | 165 | 0,975 |

| 50 | 55,7 | 0,7 | 200 | 1,498 |

| 65 | 70,7 | 0,7 | 260 | 1,926 |

| 80 | 87,4 | 0,7 | 310 | 2,960 |

| 100 | 107,4 | 1,0 | 370 | 3,655 |

| 125 | 134,1 | 1,5 | 425 | 5,868 |

| 150 | 159,1 | 1,5 | 463 | 6,995 |

| 200 | 211,4 | 1,7 | 550 | 12,095 |

Technical characteristics "GUPA"

| G U P A | ||||

|---|---|---|---|---|

| diameter ( mm) | minimal bending radius +10% | mass tol. ± 10% | ||

| nominal inside | outside | tolerance | ||

| DN=d (mm) | D (mm) | ± mm | Rmin(mm) | kg/m |

| 6 | 8,5 | 0,2 | 43 | 0,079 |

| 8 | 10,5 | 0,3 | 48 | 0,126 |

| 10 | 12,5 | 0,3 | 53 | 0,153 |

| 12 | 14,7 | 0,3 | 55 | 0,179 |

| 15 | 17,7 | 0,3 | 65 | 0,220 |

| 20 | 22,7 | 0,3 | 75 | 0,287 |

| 25 | 28,5 | 0,5 | 85 | 0,446 |

| 32 | 35,5 | 0,5 | 105 | 0,563 |

| 40 | 44,6 | 0,5 | 125 | 0,895 |

| 50 | 55,7 | 0,7 | 150 | 1,435 |

| 65 | 70,7 | 0,7 | 195 | 1,845 |

| 80 | 87,4 | 0,7 | 235 | 2,810 |

| 100 | 107,4 | 1,0 | 290 | 3,480 |

| 125 | 134,1 | 1,5 | 350 | 5,670 |

| 150 | 159,1 | 1,5 | 425 | 6,760 |

| 200 | 211,4 | 1,7 | 600 | 11,00 |